The screw assembly design is usually derived from analytical calculations. Most of the time, this method is legitimate and provides relatively accurate results. But increasingly, special cases appear that require a finite element modeling:

- Tight screws can experience non-standard sollicitations that cannot be taken into account by the analytical calculations;

- The assemblies can be submitted to thermal expansion originating in non-homogeneous temperature field;

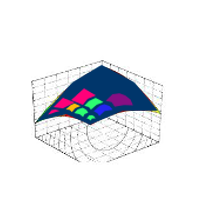

- The stress field generated by the screw connections can overlap locally to another field generated by an external load;

- It is sometimes necessary to master the screw tightening torque consumption due to tensions and friction losses between the different involved contacts;

- Assemblies can be subjected to shocks, challenging the screw holding by another physical phenomenon than typically envisioned by the analytical criteria;

- …

The expertise of AROBAS Technologies in these models results from over 15 years of experience on complex matters involving screw assemblies