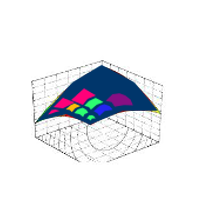

The welded seams behavior is particularly complicated to estimate with a numerical simulation.

On one hand, the metallurgical state changes due to the welding process make any homogeneous modeling too simplistic to be representative of reality. On the other hand, local stress concentrations require an in depth and costly solid geometric model, which can be disadvantageous, especially if the welded assembly has a significant number of welded seams.

The engineers of AROBAS Technologies implement a model and calculation methodology for welded seams (sheet or streamlined steel) that:

- Represents in a realistic manner the welded connection stiffness (using a shell element model);

- Calculates the static or fatigue behavior, based on analytical stress calculations, considering the nodal efforts passing through the finite element model, keeping in mind the EUROCODE 3 standards;

- Reduces the model avoiding an unnecessary detailed solid representation of the welds.

Compared to other existing similar methods, the one we use has proven to be the best time / results compromise.